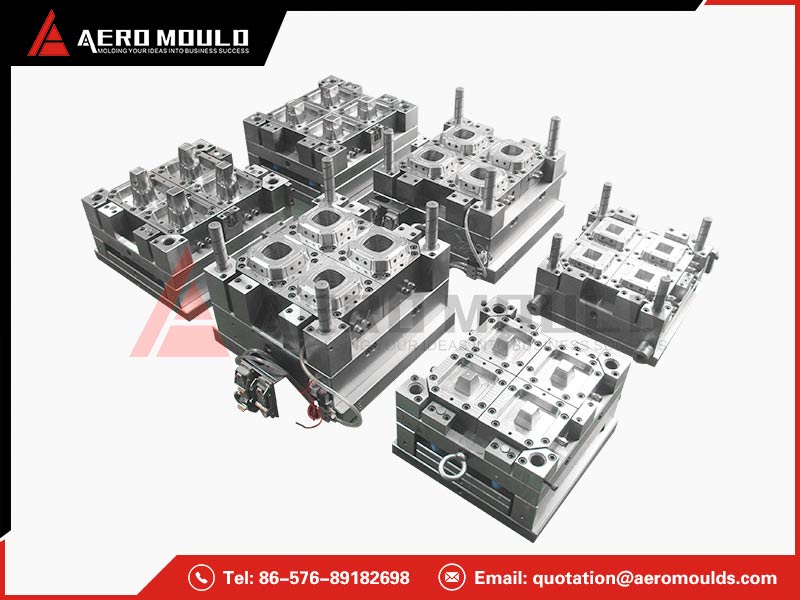

Aero Mould Co., Ltd

Mobile/whatsapp: 0086-13666469798

Add: 18# KaiTuo Road, XinQian Street, Huangyan District, Taizhou, Zhejiang, China

First, mold opening direction and parting line When des […]

First, mold opening direction and parting line

When designing each injection molded product, we must first determine its mold opening direction and parting line to ensure that the core pulling slider mechanism is reduced as much as possible and the influence of the parting line on the appearance is eliminated. Mold processing

1. After the mold opening direction is determined, the structure of the product's ribs, buckles, protrusions, etc. should be designed to be consistent with the mold opening direction as much as possible to avoid core pulling to reduce stitching lines and extend the life of the mold. Injection

2. After the mold opening direction is determined, the appropriate parting line can be selected to avoid undercuts in the mold opening direction to improve appearance and performance. Mould injection

Second, the draft angle

1. Appropriate stripping angle can avoid product pulling (drawing). The release slope of the smooth surface should be ≥0.5 degrees, the surface of fine skin lines (sand surface) is greater than 1 degree, and the surface of coarse skin lines is greater than 1.5 degrees. Plastic mould factory

2. Appropriate stripping slope can avoid product top damage, such as top white, top deformation, top break. Mold injection

3. When designing deep cavity products, the slope of the outer surface should be greater than the slope of the inner surface as much as possible to ensure that the mold core is not offset during injection, to obtain a uniform product wall thickness, and to ensure the material strength of the product opening. Mould factory

Third, product wall thickness

1. All kinds of plastics have a certain wall thickness range, generally 0.5 ~ 4mm, when the wall thickness exceeds 4mm, it will cause too long cooling time, produce shrinkage and other problems, should consider changing the product structure. Plastic mould

2. Uneven wall thickness will cause surface shrinkage. Plastic mold opening

3. Uneven wall thickness can cause blowholes and weld marks. Plastic mold opening customization

Mobile/whatsapp: 0086-13666469798

Add: 18# KaiTuo Road, XinQian Street, Huangyan District, Taizhou, Zhejiang, China