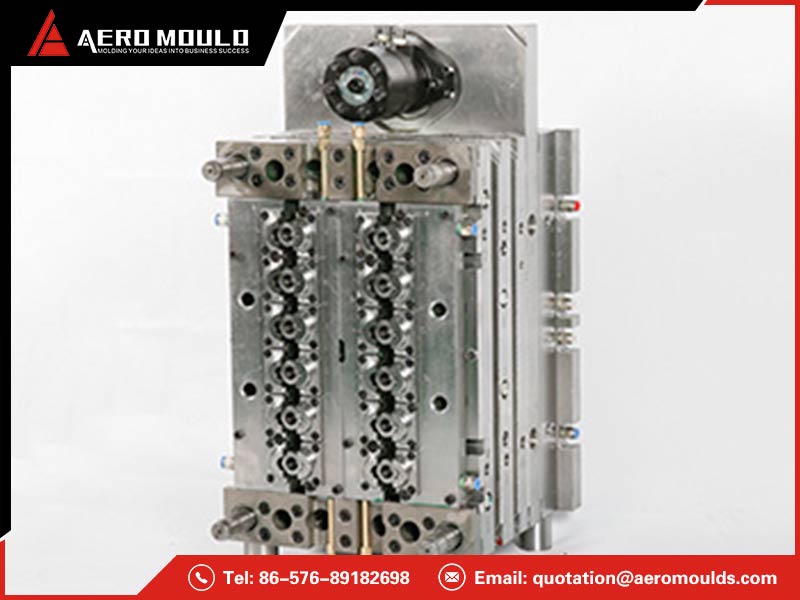

Aero Mould Co., Ltd

Mobile/whatsapp: 0086-13666469798

Add: 18# KaiTuo Road, XinQian Street, Huangyan District, Taizhou, Zhejiang, China

1. The injection mold is large in size, and it takes a […]

1. The injection mold is large in size, and it takes a lot of time to replace a single cavity; each mold cavity is relatively independent and can be replaced independently;

2. The cap molding machine is a special machine for bottle caps, which has a special demoulding plan for the caps; the cap injection molding machine has no special plan for the caps at all, so the caps can be molded into bell mouths with high suspension rate. , Users like to use.

3. The injection cap needs to heat the material to a molten active state at a temperature of about 250°C; compression molding only needs to be heated to about 180°C, and the energy consumption of the injection cap is higher than that of the injection cap.

4. Compression molding has low processing temperature, less shortening, and more accurate bottle cap size;

5. Injection molding fills all cavities at one time, and extrudes one cap material each time. The extrusion pressure of compression molding is very small, while the demand pressure of injection molding is relatively high.

Aviation Mould Co., Ltd. is located in Huangyan, the "Hometown of Chinese Moulds". We have been committed to the development and manufacture of various high-quality molds, including high-speed thin-wall molds, two-color molds, multi-cavity lid molds, household appliances molds, pipe fitting molds, etc.

Our company takes quality as its life and has established the strategic goal of "high standards, high precision, and high efficiency". Based on the work style of "honest and pragmatic, indomitable, teamwork spirit, and achievement of excellence", the company sincerely invites potential customers from all over the world to come and work with them to create a better future.

Mobile/whatsapp: 0086-13666469798

Add: 18# KaiTuo Road, XinQian Street, Huangyan District, Taizhou, Zhejiang, China